Highest Temperature Heating Available!

PTFE Inline Chemical Heater - Electric Inline Heater

Best-in-class chemical heater

The Inline Chemical Heater offers unmatched performance and reliability with the ability to heat a variety of chemicals. This heater is suitable for either single pass or recirculating applications. Delivers best-in-class performance over a wide range of flow and temperature requirements. The TIH is the most durable and long-lasting inline chemical heater available! Multiple plumbing layouts facilitate easy installation into a variety of tool configurations. Fluoropolymer (PTFE) surfaces protect from permeation. Heats up to 210°C (410°F)

Applications

Semiconductor Wet Processes

Sterilization/Cleaning

Solar/Photovoltaic Wafer Cleaning

PRODUCT DESCRIPTION

Unmatched in Semiconductor process fluid heating. Single chamber sizes up to 18kW

FEATURES

Ruggedly designed for the most demanding recirculation or single pass chemical applications.

Able to achieve the highest temperature heating, up to 210°C.

All fluoropolymer wetted surfaces for virtually any wet chemistry application. Thick walled chamber provides long service life in the harshest high temperature applications.

Long heater life for reduced cost of ownership (COO): Patented heater gas purge system continuously removes any chemical permeation and ensures long element life.

Certification: CE, UL compliant, Semi S2

SPECIFICATIONS

1,000 watts up to 18,000 watts

200 to 600 volts, single or three phase (12kW and larger require three phase)

Watt Density: 10 watts per square inch (1.5w/cm2)

Fluid Connections: ¼-inch (6mm) to 1-inch (25mm); ½-inch (12mm) to 1-inch (25mm) Super 300 Type Pillar®

Element Purge: Small amount of clean dry air (CDA) or N2 gas flows between the metal grounded element and the PTFE sheath. Purge minimizes potential for ionic contamination. Removes chemical permeation for longer service life

OPTIONS AVAILABLE (CONSULT FACTORY)

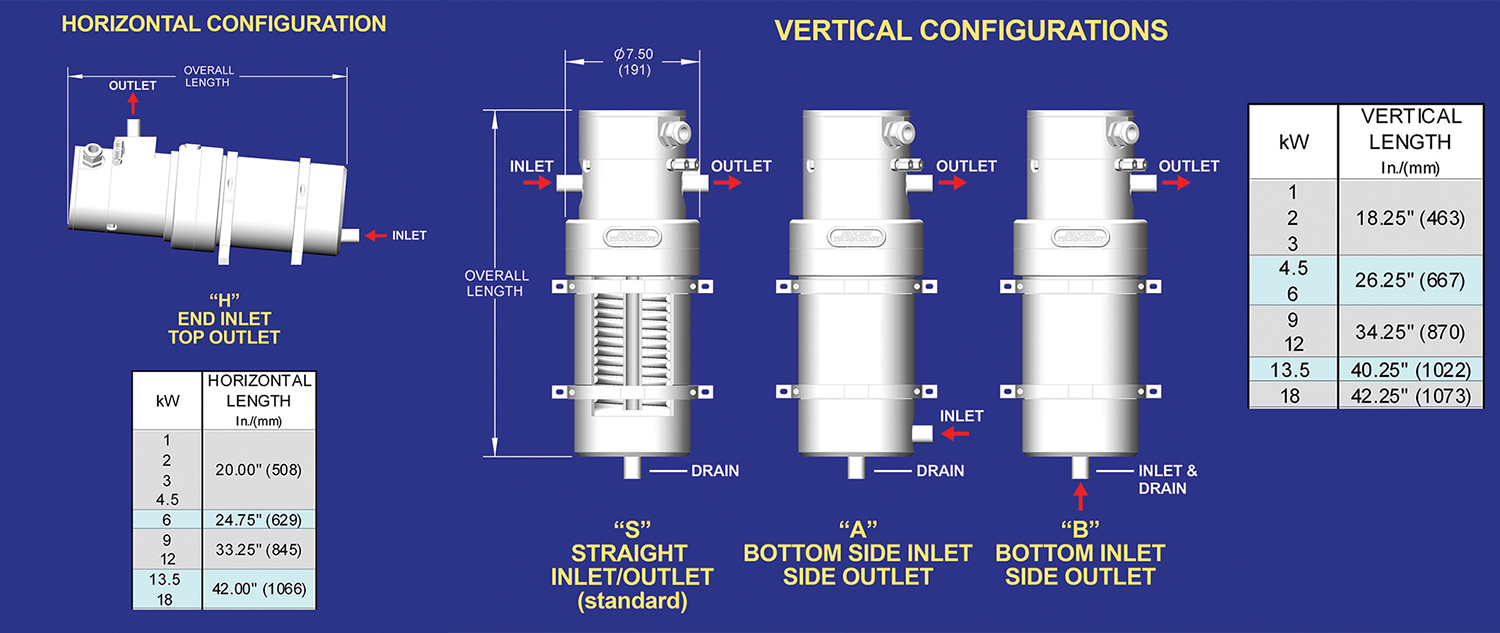

Horizontally mounted configuration

PVDF high temperature mounting brackets

Custom configurations, connections and cable lengths

Capacitive style liquid level verification